|

|

by Marcia Napier, Grain Valley Historical Society I grew up seeing Great-Grandpa Sanders and Uncle Dave’s cane mill in my aunt’s backyard. It is another one of those “old things” about which I wish I had asked more questions. I’m guessing that in the late 1800s nearly every farmer in Jackson County must have grown sorghum. I’m also guessing that granulated sugar might have been a luxury in those days.

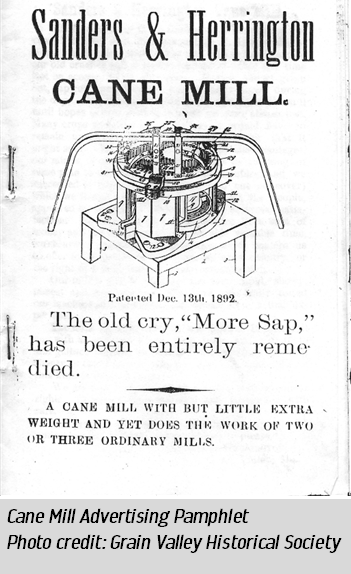

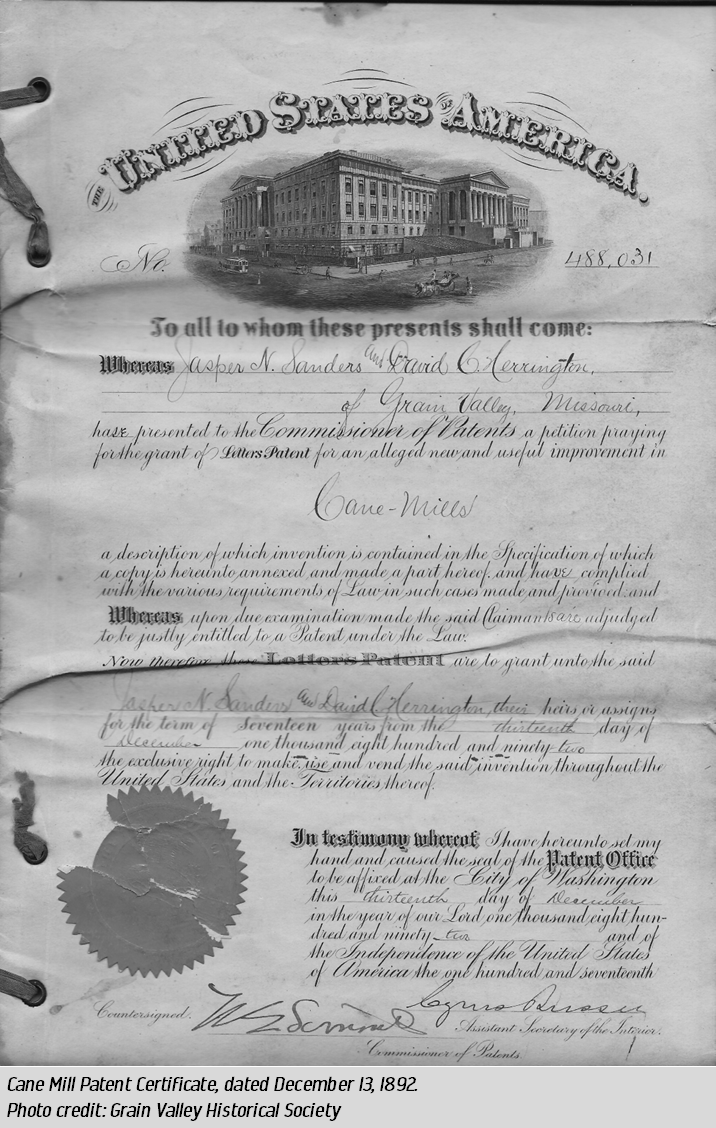

My grandmother always talked about using sorghum and molasses in recipes and a quick look through old recipes books verifies their use along with honey as the primary sweeteners in that time. While molasses is usually made from sugar cane or sugar beets, it is also possible to extract molasses, as well as sorghum, from the cane of the sorghum plant. Their cane mill received a patent on December 13, 1892 and the following statement could be found in a small pamphlet advertising. “While engaged in the manufacture of sorghum a few years back, we J. N. Sanders and D. C. Herrington, of Grain Valley, Mo., realized the very slow movement of our old crusher and the great amount of labor and time lost on account of its slowness. Horses almost given out, sap run down and fire cooled many times during the day. People’s cane would stand stacked at the mill until hopes of ever getting it made up were almost lost. Many crops we failed to get for fear it would have to remain unworked until freezing weather, or that it might sour. With all the above-named disadvantages, our minds, of course, were naturally put to thinking of some plan to do away with the old troubles; and we succeeded in inventing a machine which we thought would be endorsed by the people, approved by the patent office and give universal satisfaction. So, with an output of a nice little sum of money and the forfeiture of considerable valuable time, we secured a patent of our invention which enables us to offer to the people of this immense can country, or the right of a mill, that will make investors rich. Our mill is simple, durable and very rapid, showy, honest and inexpensive. We have practically tested our machine and, therefore, can speak from actual experience. The mills we now have in use have a 12-inch roll and with an ordinary beam, from three and a half to four gallons sap can be crushed per minute, or from twenty to thirty tons of can per day. A cane mill of this kind is worth a farm. We are now ready to sell mill, entire, state or county rights, Correspondence solicited and considered care. For proof to what we have said first correspond with our endorsers. We are yours anxious to please.” Sanders & Herrington Grain Valley, Mo The advertising pamphlet contains over twenty testimonial letters. Here are a couple of samples. If you have driven around Grain Valley very much, you might recognize the names. Grain Valley February 22, 1894 This certifies that the Sanders & Herrington Cane Mill, in my opinion, is the best mill on the market. It works with perfect satisfaction; high runner and does lots of work. Respectfully, Jesiah Seymore Grain Valley, 1894 It has been my pleasure to travel through many of the sorghum states throughout the Union and have examined all the latest improved cane mils and think your mill will do double the amount of work with less draft on team and less work on feeder. Its bearings, if properly adjusted, I consider perfect—but little friction. I am Yours, Joe M. Potts Visit the Grain Valley Historical Society to see the inside workings of the old mill along with the application, certificate and other legal papers and letters involved with securing of the patent. Comments are closed.

|

Categories

All

Archives

July 2024

|

Grain Valley NewsGrain Valley News is a free community news source published weekly online. |

Contact Us |

RSS Feed

RSS Feed